CERAMIC & 3D Printing Research

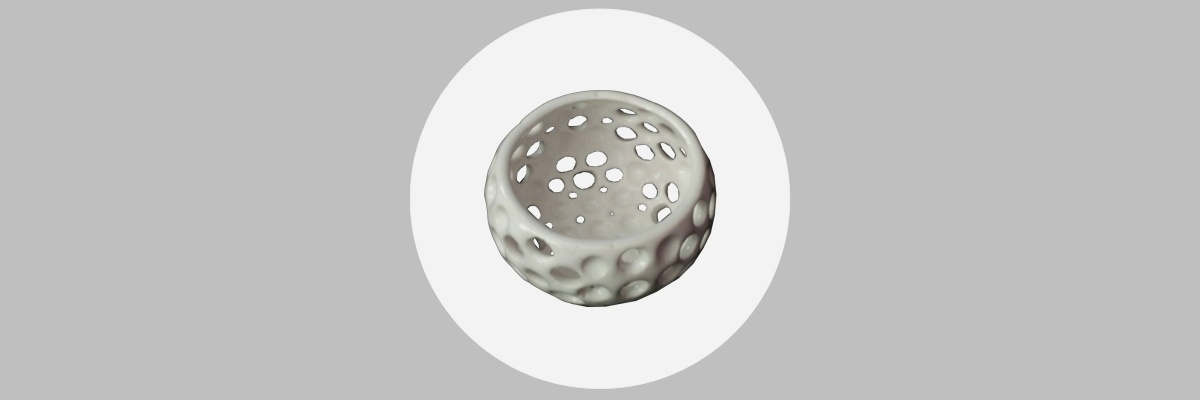

ComeTrue® M10 CERAMIC 3D printer is developed by patented ComeTrueⓇ

Binder Jetting (CBJ) 3D printing technology. Binder Jetting 3D inkjet printing

is a kind of rapid prototyping(RP) or additive manufacturing(AM) process.

With the custom ceramic powders,

it can be applied in ceramic crafts and education. It applies ceramic

composite powders and ceramic firing post-process. The shrinkage ratio after bisque

firing is around 16~17 %, it will be the same size after firing glaze.

ComeTrue® M10 3D printer can also work as inkjet-based advanced manufacturing

& 3D printing research platform. Developers may formulate powders on industrial

ceramic components, biomedical bone ceramics applications, even on polymer

powders. M10 supports flexible Z axis layer thickness options to fit for various powders.

Developers also can set up parameters on printing time and nozzle slot number

for binder jetting.